In the realm of automotive performance and industrial applications, safeguarding critical components from extreme temperatures is paramount. Black silicone heat sleeves have emerged as a crucial solution, offering superior protection against high temperatures. In this article, we delve into the significance of black silicone heat sleeves and their role in shielding your valuable equipment.

1. Understanding Black Silicone Heat Sleeve

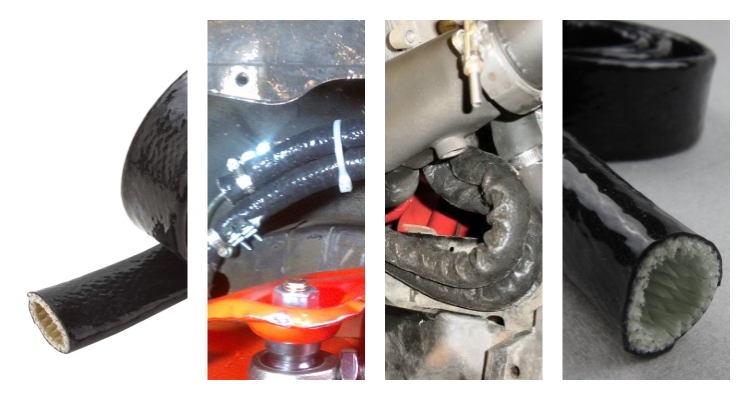

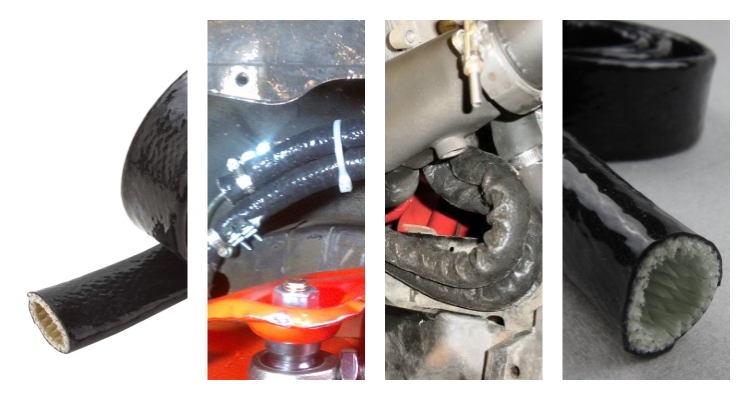

Black silicone heat sleeves

1. Understanding Black Silicone Heat Sleeve

Black silicone heat sleeves are engineered from premium-grade silicone rubber, reinforced with glass fibers. This specialized construction grants them exceptional thermal resistance, making them an ideal choice for applications requiring exposure to high temperatures. Designed to endure temperatures up to 200°C, black silicone heat sleeves serve as a protective barrier, safeguarding sensitive components from heat-induced damage.

2. Superior Protection

2.1 High-Temperature Endurance

The standout feature of black silicone heat sleeves lies in their ability to withstand high temperatures with ease. Whether in automotive engines or industrial machinery, these sleeves remain resilient even in the most demanding environments. By providing a reliable shield against extreme heat, they ensure the longevity and optimal performance of crucial components.

2.2 Effective Thermal Insulation

Black silicone heat sleeves boast excellent thermal insulation properties, effectively minimizing heat transfer to surrounding components. This feature aids in maintaining a stable temperature within the sleeve, contributing to improved overall performance and enhanced efficiency of your equipment.

3. Automotive Applications

3.1 Engine Bay Protection

In the automotive industry, black silicone heat sleeves find extensive application in engine bays. They offer protection to wiring harnesses, spark plug wires, and fuel lines from the intense heat generated by high-performance engines. By preventing heat-related issues, these heat sleeves contribute to the smooth functioning and performance of your vehicle.

3.2 Electronic Component Insulation

Modern vehicles incorporate a plethora of electronic components that are sensitive to temperature variations. Black silicone heat sleeves provide effective insulation for these electronic parts, ensuring their reliability and functionality even under extreme conditions.

4. Industrial Applications

Beyond the automotive sector, black silicone heat sleeves have a vital role in industrial applications. They protect electrical wires, cables, and hoses in manufacturing machinery and industrial equipment, safeguarding these crucial components from heat-induced breakdowns. In industrial environments with high-temperature operations, these heat sleeves become an indispensable line of defense for equipment protection.

5. Benefits of Black Silicone Heat Sleeve

5.1 Enhanced Equipment Longevity

By providing reliable protection against high temperatures, black silicone heat sleeves enhance the longevity of your equipment. They prevent premature wear and potential failures due to heat-related stress, ensuring your machinery and vehicles can operate smoothly for extended periods.

5.2 Improved Performance and Reliability

With superior thermal insulation and endurance, black silicone heat sleeves contribute to improved performance and reliability. Your equipment can function optimally without being compromised by extreme temperatures, leading to increased productivity and reduced downtime.

Conclusion

Black silicone heat sleeves represent a significant advancement in thermal protection technology, offering superior performance and a wide array of applications in the automotive and industrial sectors. By effectively shielding vital components from high temperatures, these heat sleeves ensure the longevity, efficiency, and reliability of your equipment. Whether in high-performance vehicles or industrial machinery, embracing black silicone heat sleeves is a wise investment to safeguard your valuable assets from the challenges of extreme temperatures.