The intricate design and impeccable functionality of

Glass Fibre Webbing Tape are results of a meticulous manufacturing process. Here, we pull back the curtain and delve deep into the fascinating journey from raw materials to the finished product.

Raw Material Selection

Raw Material Selection

The process begins with sourcing high-quality raw materials. Silica sand, limestone, and soda ash are the primary components used in producing the glass fibers integral to the tape.

Melting & Fiber Formation

Melting: The raw materials are melted in a furnace at temperatures exceeding 1,700°C to form molten glass.

Fiber Drawing: The molten glass is then extruded through specialized bushings, drawing it into thin fibers.

Cooling: The fibers are rapidly cooled, maintaining their slender shape and flexibility.

Weaving the Tape

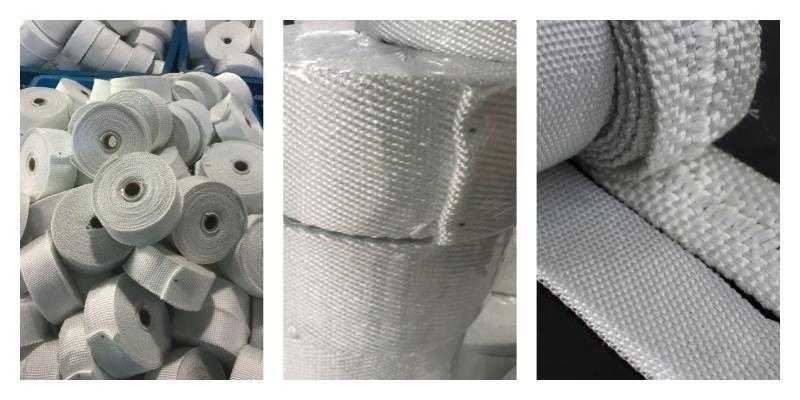

Yarn Formation: These glass fibers are wound to form yarns, which serve as the building blocks for the webbing tape.

Weaving: The yarns are woven together using advanced machinery, creating the characteristic webbed pattern of the tape.

Finishing Touches

Heat Treatment: The woven tape undergoes a heat treatment process, further enhancing its temperature-resistant properties.

Coating: Depending on the intended application, some tapes receive a special coating to add qualities like enhanced chemical resistance or adhesive backing.

Quality Assurance

Each batch of Glass Fibre Webbing Tape undergoes rigorous testing. From tensile strength to thermal resistance, every aspect is scrutinized to ensure it meets industry standards.

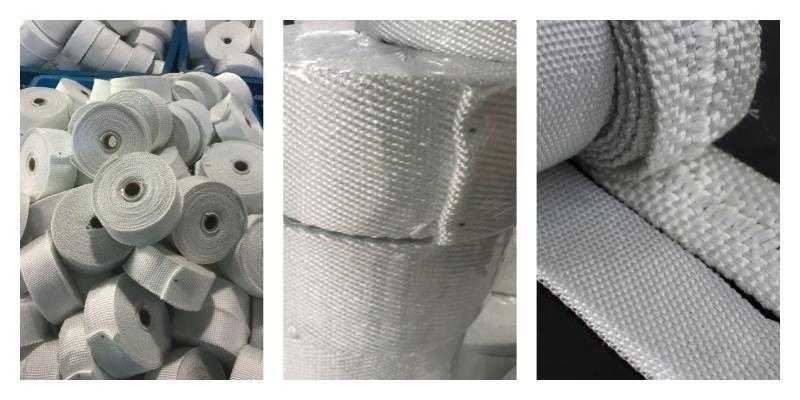

Packaging and Dispatch

Once approved, the tapes are rolled, packaged, and dispatched to various industries worldwide, ready to play their pivotal role in insulation and protection.

Conclusion

The manufacturing of

Glass Fibre Webbing Tape is a testament to the blend of art and science. It showcases how precision, expertise, and dedication culminate in a product that has become an industry staple.