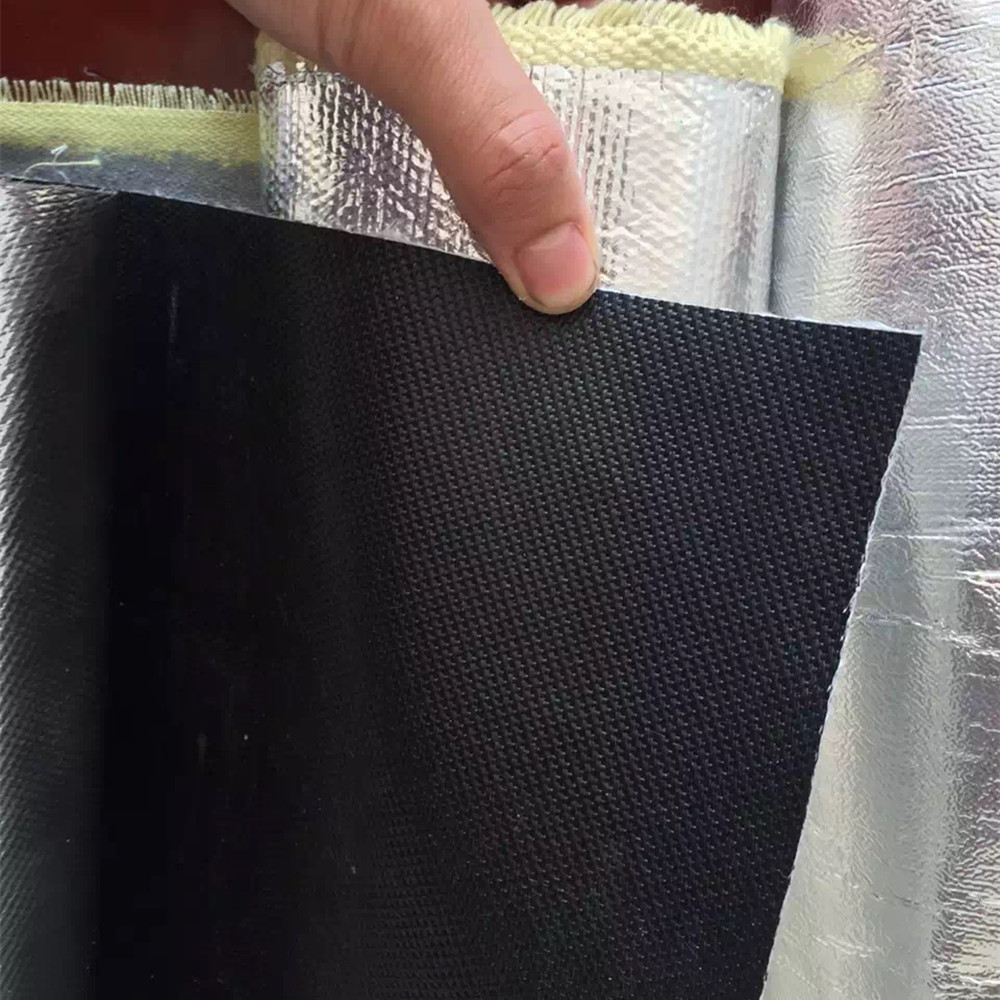

Aluminized PU (Polyurethane) Coated Fiberglass Fabric is a specialized type of fabric that combines the heat-resistant properties of fiberglass with a layer of aluminum and a polyurethane coating. Here's a breakdown of its components and features:

Fiberglass Base: The core material is fiberglass, which provides excellent thermal resistance and mechanical strength. Fiberglass is known for its high heat resistance, typically able to withstand temperatures up to 1000°F (537°C) or more, depending on the specific type of fiberglass.

Aluminized Coating: The fiberglass fabric is coated with a thin layer of aluminum, which adds reflective properties. This aluminized layer helps to reflect heat away from the surface, further enhancing the fabric's heat resistance and making it ideal for applications involving high temperatures or radiant heat.

PU Coating: The polyurethane (PU) coating adds additional durability, flexibility, and water resistance to the fabric. The coating helps to improve the fabric's resistance to abrasion, chemicals, and moisture, making it suitable for harsh environments.

This material is often seen in industries like automotive, aerospace, and manufacturing, where heat management is critical for the safety and longevity of equipment.