The differences between silicone fire sleeve and nylon hose sleeve for hydraulic hoses can be understood through several key factors:

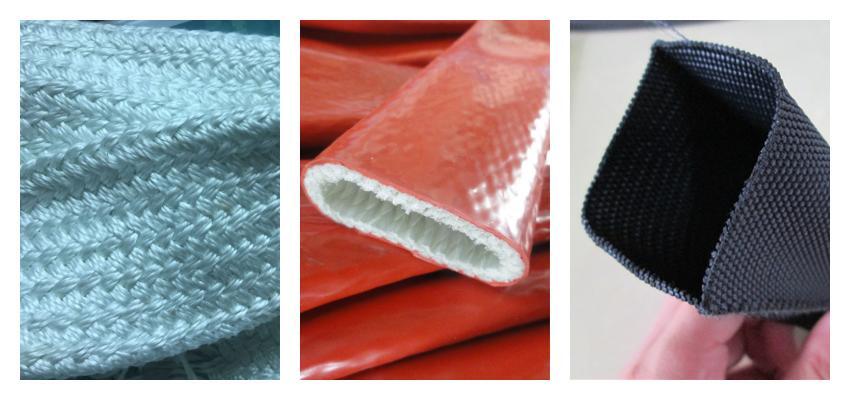

Silicone Fire Sleeve: Made from silicone rubber, often reinforced with fiberglass or other high-temperature materials.

Nylon Hose Sleeve: Constructed from nylon, a durable synthetic polymer, sometimes blended with other materials for enhanced properties.

Silicone Fire Sleeve: Designed for fire and extreme heat resistance. Protects hoses from flames, sparks, and high-temperature environments (e.g., industrial furnaces, engines).

Nylon Hose Sleeve: Focuses on mechanical protection against abrasion, cuts, impacts, and UV exposure. Common in construction or mining equipment.

Silicone: Withstands temperatures up to 500°F (260°C) or higher, retaining flexibility under heat.

Nylon: Typically resistant up to 250°F (120°C). May melt or degrade at higher temperatures.

Silicone: Resistant to oils, fuels, and many chemicals, but may degrade with prolonged exposure to solvents.

Nylon: Good resistance to oils and abrasives but can absorb moisture, potentially leading to swelling or weakening.

Silicone: Remains flexible in extreme temperatures but may be bulkier.

Nylon: Lightweight and flexible but can stiffen or become brittle under heat or UV exposure.

Silicone: Used in high-risk environments (e.g., aerospace, automotive engines, steel mills).

Nylon: Ideal for rugged environments with physical wear (e.g., agricultural machinery, hydraulic systems exposed to friction).

Silicone: Generally more expensive due to specialized materials and certifications (e.g., SAE J2308).

Nylon: Cost-effective for general-purpose protection.

Silicone: Often meets strict fire safety standards (e.g., ISO 15540 flame resistance tests).

Nylon: Prioritizes abrasion resistance without specific fire certifications.

Silicone: May require heat-resistant adhesives or clamps; longer lifespan in high-heat settings.

Nylon: Easier to install via slip-on or wrap designs; may need frequent checks in harsh conditions.

UV/Moisture Resistance: Silicone excels in UV resistance; nylon may require treatments for moisture.

Weight: Nylon is lighter, beneficial where weight matters.

|

Feature |

Silicone fire sleeve | Nylon hose sleeve |

|

Primary Use |

Fire/heat protection |

Abrasion/physical damage |

|

Max Temperature |

~500°F+ (260°C+) |

~250°F (120°C) |

|

Key Strength |

Flame resistance, flexibility |

Lightweight, abrasion resistance |

|

Cost |

Higher |

Lower |

|

Environment |

High-heat, fire-prone areas |

Rugged, high-wear settings |

Choose silicone for fire-prone/high-heat applications and nylon for physical wear protection in moderate temperatures. Consider environmental factors, compliance needs, and budget when selecting.