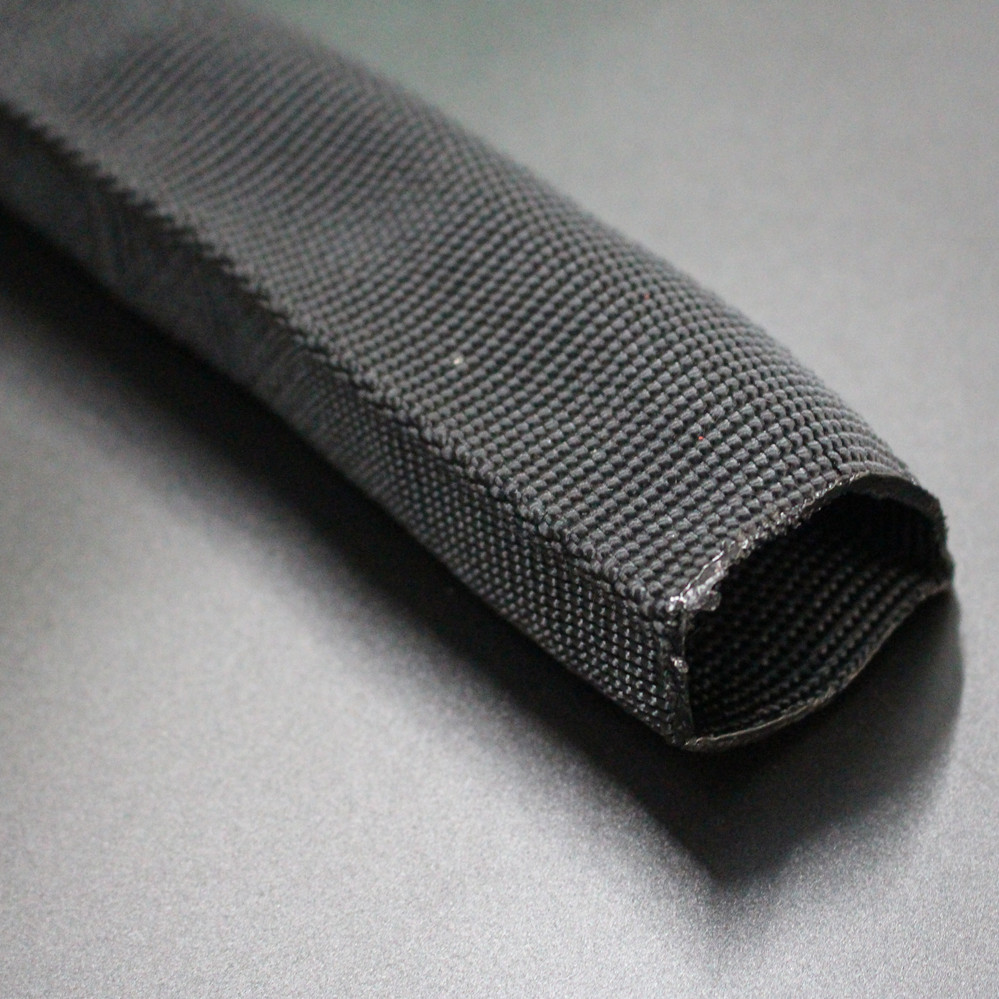

A textile protection sleeve is a specially designed cover made from advanced textile materials intended to shield various types of equipment from wear, abrasion, and environmental damage. These sleeves offer a combination of durability, flexibility, and resistance, making them invaluable in numerous industrial and mechanical applications.

Abrasion Resistance: Textile protection sleeves are engineered to withstand significant wear and tear, extending the lifespan of the equipment they cover. The high-quality fibers used in these sleeves resist fraying and breaking, providing a robust barrier against abrasive forces.

Flexibility and Adaptability: Unlike rigid protective casings, textile sleeves are flexible, allowing them to conform to various shapes and sizes. This adaptability ensures a snug fit and effective protection across different types of equipment.

Thermal Insulation: Many textile protection sleeves offer thermal insulation, helping to protect equipment from extreme temperatures. This feature is crucial in environments where heat or cold could affect the performance or safety of the equipment.

Chemical Resistance: Some textile sleeves are treated to resist chemicals, oils, and other corrosive substances. This property is essential for protecting equipment used in harsh chemical environments.

Easy Maintenance: Textile sleeves are often easy to clean and maintain. They can typically be washed or replaced without significant effort, making them a practical choice for ongoing use.

Hydraulic Hose Protection: Hydraulic hoses are vital components in machinery that operate under high pressure and extreme conditions. Using textile protection sleeves on hydraulic hoses helps safeguard them from abrasion, hydraulic fluid leaks, and environmental factors. For instance, in construction machinery, textile sleeves can prevent hose damage caused by friction with other parts or exposure to harsh weather conditions.

Chain Protection: Chains used in industrial machinery or automotive applications can experience significant wear from friction and contaminants. Textile sleeves protect chains by reducing frictional wear and shielding them from dust, debris, and corrosive substances. In manufacturing settings, these sleeves help maintain the efficiency and longevity of conveyor chains, reducing maintenance needs and downtime.

Cable and Wire Protection: Cables and wires are essential for the operation of various systems, including electrical and data transfer networks. Textile protection sleeves cover cables to prevent damage from abrasion, impact, and exposure to chemicals. For example, in aerospace and automotive industries, these sleeves ensure that wiring remains intact and functional despite the rigors of movement and vibration.

Pneumatic Hose Protection: Pneumatic hoses, like hydraulic hoses, are exposed to high pressure and potential abrasion. Textile sleeves help maintain the integrity of these hoses by providing an extra layer of protection against external damage. In automated manufacturing systems, this protection ensures that pneumatic systems operate smoothly and reliably.

John, a Construction Equipment Manager: “We use textile protection sleeves on all our hydraulic hoses. They’ve made a huge difference in reducing wear and extending the life of our hoses. With the sleeves, we don’t have to replace hoses as frequently, saving us both time and money.”

Sarah, an Automotive Technician: “The textile sleeves we use for our chains have been fantastic. They keep the chains clean and free from debris, which helps with smoother operation and less frequent maintenance.”

Mike, an Aerospace Engineer: “For our wiring harnesses, textile sleeves are a must. They provide the protection we need against extreme temperatures and mechanical wear, which is crucial for the reliability of our systems.”

Textile protection sleeves are essential tools for enhancing the durability and longevity of various types of equipment. By providing protection against abrasion, environmental factors, and chemical exposure, these sleeves help maintain optimal performance and reduce maintenance needs. Whether used for hydraulic hoses, chains, cables, or pneumatic hoses, textile protection sleeves offer a versatile and effective solution for protecting valuable equipment across multiple industries.