Heat Shrink-ability

Thermal shrinkage ratio: 2:1

The wall thickness of braided pipe after full shrinkage is about 1.0 mm

Longitudinal change after complete contraction: - 10 ~ - 20%

Temperature Grade

Operating temperature range (3000 hours): - 40 ℃ ~ 125 ℃

Service temperature range (1000 hours): - 40 ℃ ~ 150 ℃

Minimum shrinkage temperature: 110 ℃

Recommended shrinkage temperature: 120 ℃ ~ 150 ℃

Maximum storage temperature: 50 ℃

Materials

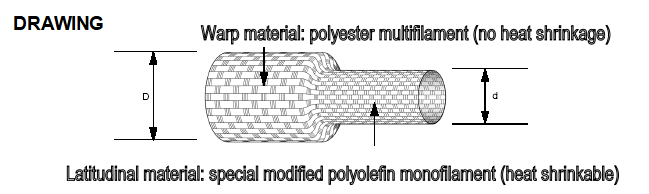

Warp material: polyester multifilament

Latitudinal material: irradiation crosslinking, modified polyolefin (PE-7042)

Coating material: modified polyolefin

Basic performance

|

Performance |

TEST |

RESULT |

|

Wear resistance: (200g load, 0.3mm metal knife edge, 10Hz, 10min stroke, 144000 cycles) |

23℃ |

The protected rubber pipe fittings are not worn |

|

80℃ |

The protected rubber pipe fittings are not worn |

|

|

125℃ |

The protected rubber pipe fittings are not worn |

|

|

Thermal aging property |

168小时,125 ℃ |

The wear resistance is not weakened at 23 ℃ |

|

24小时,150 ℃ |

The wear resistance is not weakened at 23 ℃ |

|

|

Flame retardancy |

MVSS 302 |

Uncracked |

|

Low temperature flexibility |

-40℃ 4 hours |

Uncracked |

|

Solvent resistance: 1. Antifreeze (50% glycol) 2. Engine oil (SAE 10W / 30) 3. Mineral hydraulic fluid 4. Detergent (1% active agent) 5. Brake oil (DOT 4) 6. Unleaded gasoline 7. Diesel oil |

Soak at 23 ℃ for 24 hours |

The wear resistance is not weakened at 23 ℃ |