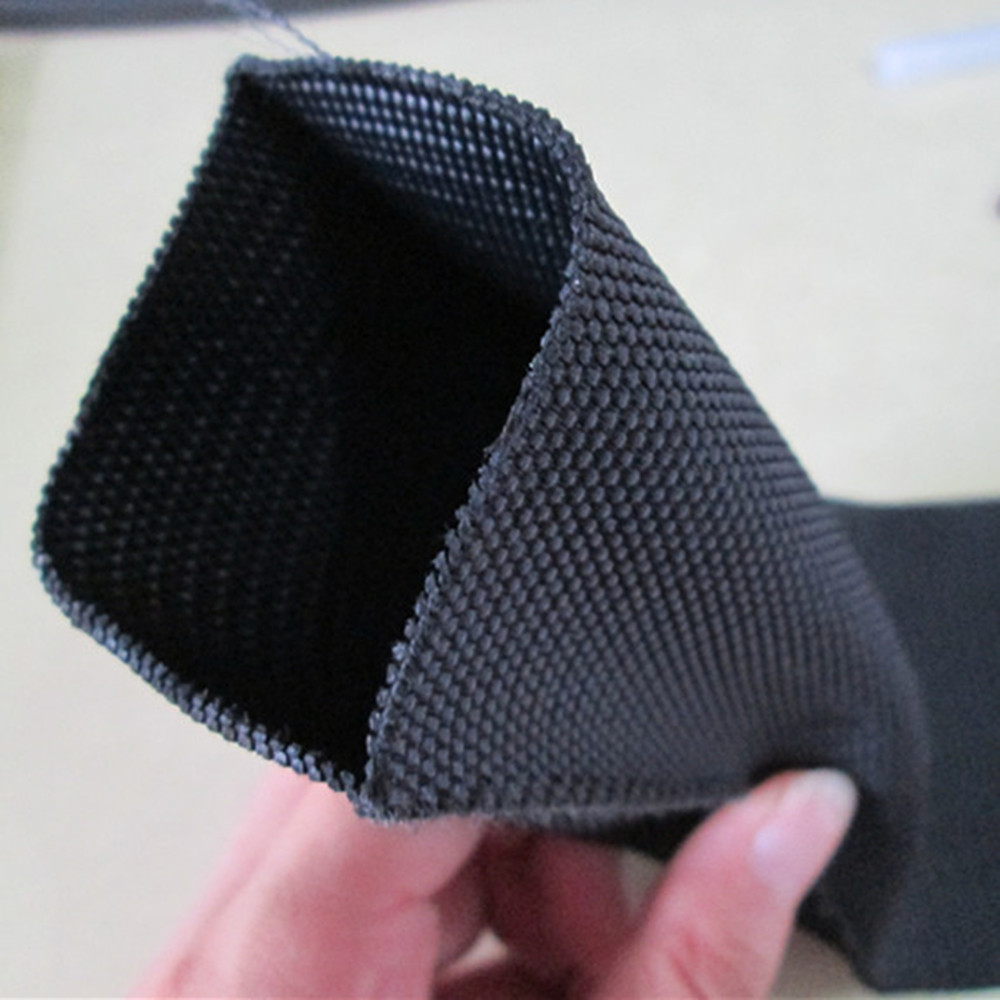

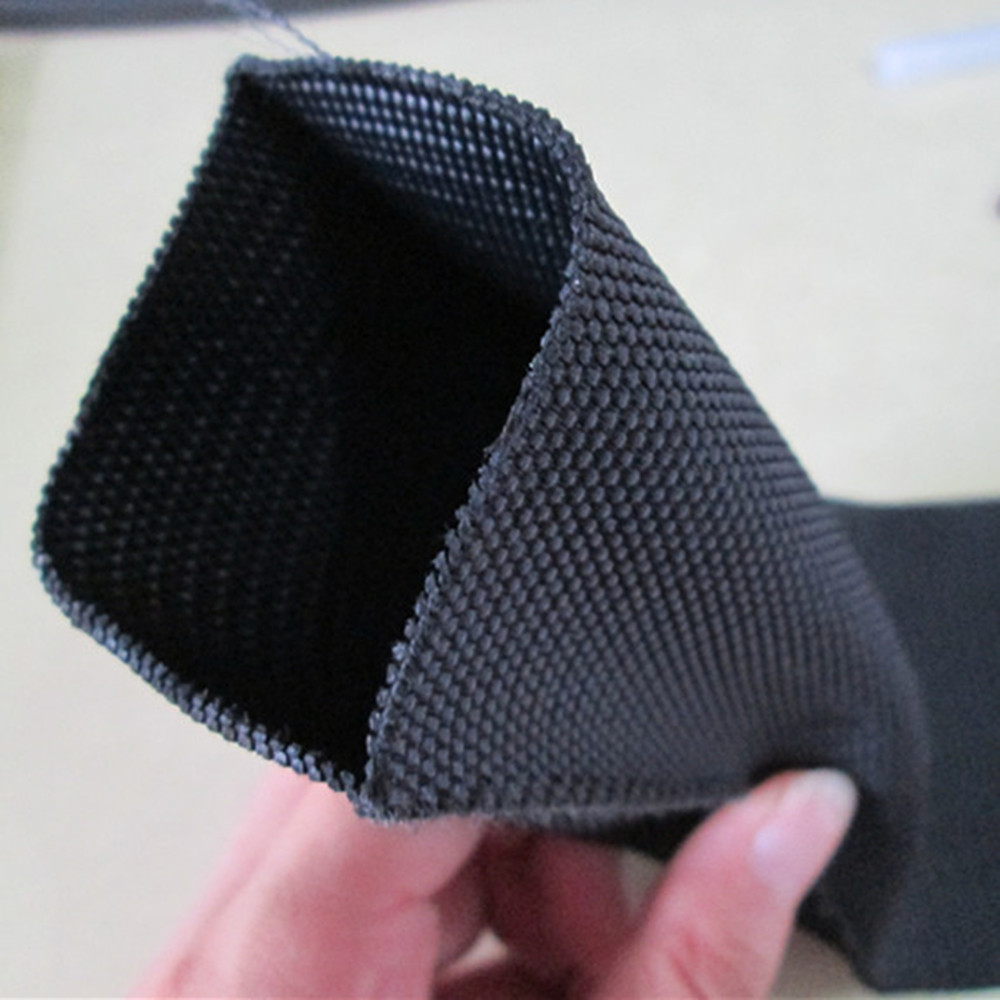

A nylon protective sleeve is typically made from nylon fabric, which is a synthetic polymer. Nylon is known for its strength, durability, and resistance to abrasion, making it an excellent material for protective sleeves.

Composition and Features:

-

Material: Nylon is a synthetic fiber derived from petrochemicals, often polymerized into a material that is strong and flexible.

-

Structure: The sleeve usually has a woven or knitted structure that allows it to be flexible yet tough.

-

Coating: Sometimes, nylon sleeves are coated with additional materials to enhance properties like water resistance or to provide a smooth surface for easier sliding.

Uses and Benefits:

-

Protection: Nylon sleeves protect cables, hoses, wires, and other objects from abrasion, cuts, and general wear and tear. They also shield against dust and dirt.

-

Insulation: They can provide a layer of insulation, helping to prevent electrical shorts or damage to sensitive equipment.

-

Appearance: They help in organizing and bundling cables or wires, which can improve the appearance and manageability of a setup.

-

Cost-effective: Nylon is relatively inexpensive compared to some other materials, making it a cost-effective choice for protective applications.

In summary, nylon protective sleeves offer a blend of durability, flexibility, and protection, making them useful in various industrial, technical, and everyday applications.