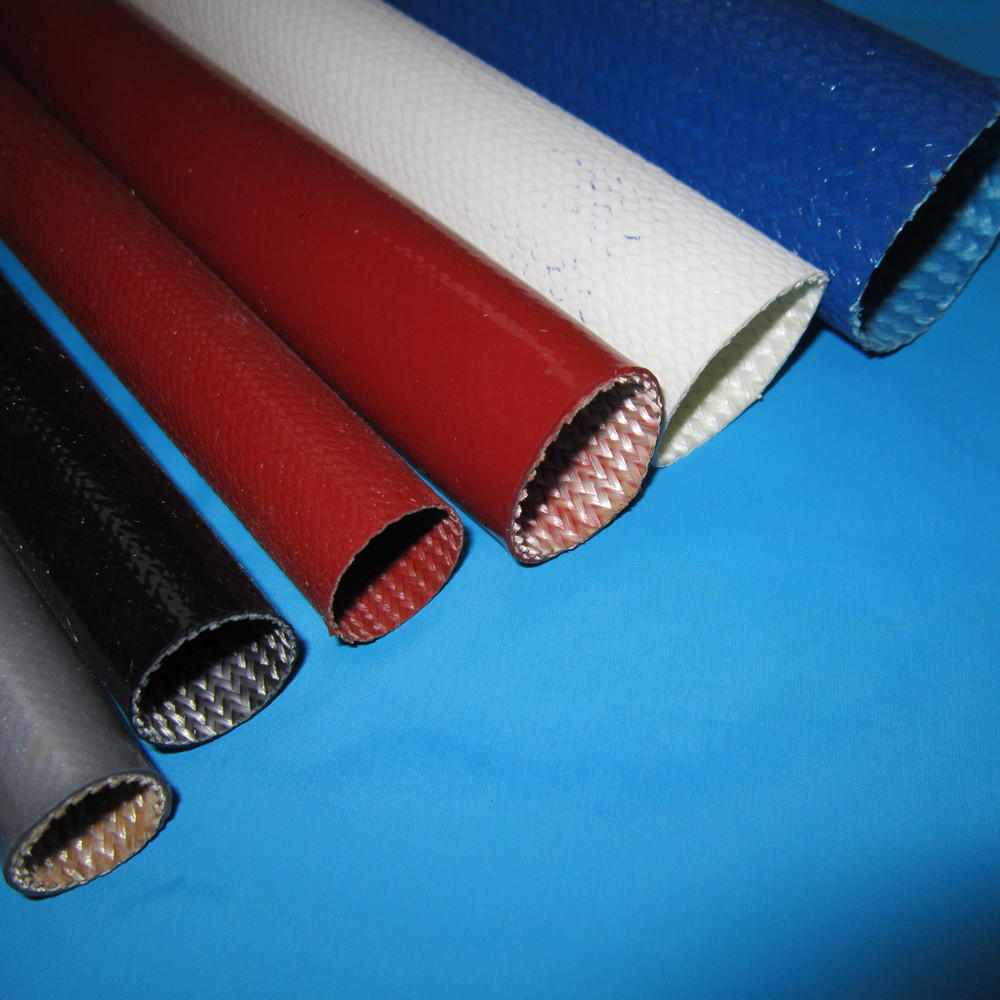

The Silicone Coated Fiberglass Sleeve provides advanced protection for wires, cables, hoses, and hydraulic lines in environments where extreme heat, abrasion, and chemicals are present. Combining the flexibility of fiberglass with a durable silicone outer layer, this sleeve is designed to shield components from high temperatures, mechanical damage, and fluid exposure. Its versatility makes it a trusted solution across a variety of industries, including automotive, aerospace, heavy equipment, and power generation.

Superior Heat Resistance: The fiberglass core offers excellent thermal insulation, while the silicone coating adds an extra layer of heat protection. This sleeve is capable of withstanding continuous exposure to temperatures as high as 260°C (500°F) and short bursts up to 1,100°C (2,012°F), making it ideal for protecting components in high-temperature environments.

Abrasion and Chemical Resistance: The silicone coating provides exceptional resistance to wear and tear, as well as protection against oils, chemicals, and solvents. This makes it suitable for use in applications where hoses, wires, and cables are exposed to harsh working conditions.

Flexible and Easy to Install: Despite its high durability, the sleeve remains flexible, allowing for easy installation over complex shapes, bends, and fittings. It can be applied to both new and existing assemblies without the need to disconnect parts, minimizing downtime during maintenance.

Moisture and Fluid Resistance: The silicone layer repels water, ensuring protection against moisture, steam, and fluids that could otherwise corrode or damage sensitive components. This feature is especially useful in environments like marine, automotive, or chemical processing plants.

Electrical Insulation: The fiberglass provides excellent dielectric strength, making the sleeve ideal for insulating electrical wires and protecting against short circuits in high-voltage applications.

Automotive Industry: Automotive engineers rely on Silicone Coated Fiberglass Sleeves to protect hoses, fuel lines, and electrical wiring from heat generated by engines and exhaust systems. The sleeve is particularly valuable for turbocharged or high-performance vehicles, where elevated temperatures can quickly degrade unprotected components.

User Testimonial:

"We use this sleeve to wrap the wiring harness and fuel lines in high-performance cars. It withstands extreme heat and provides excellent insulation, ensuring reliable performance during races." – Automotive Engineer, USA

Aerospace Industry: In aerospace applications, this sleeve is used to shield hydraulic lines, cables, and avionics from the intense heat generated by jet engines and other critical systems. Its lightweight design and high-temperature resistance make it indispensable in environments where weight and safety are top priorities.

User Testimonial:

"The silicone-coated fiberglass sleeve has been a crucial part of our thermal protection strategy. It performs well under the extreme temperatures and stresses that come with aerospace operations." – Aerospace Technician, Germany

Heavy Equipment and Industrial Machinery: Heavy machinery operators use Silicone Coated Fiberglass Sleeves to protect hydraulic hoses and cables from both high temperatures and abrasive wear. In mining, construction, and manufacturing, equipment often operates in extreme conditions where heat, mechanical stress, and exposure to fluids can lead to failures. This sleeve extends the life of critical components, reducing downtime and maintenance costs.

User Testimonial:

"We installed the sleeve on our hydraulic lines to prevent abrasion and heat damage. It’s incredibly durable, even in our toughest operating conditions. We’ve noticed fewer leaks and less maintenance overall." – Maintenance Supervisor, Canada

Power Generation: In power plants, this sleeve is often used to insulate wiring, cables, and fluid transfer systems exposed to high temperatures and electrical fields. The combination of thermal and electrical insulation ensures safe and reliable operation of equipment like generators, turbines, and transformers.

User Testimonial:

"The silicone-coated fiberglass sleeve protects the high-voltage cables in our power plant from both heat and abrasion. It’s been instrumental in improving the safety and reliability of our operations." – Electrical Engineer, Japan

The Silicone Coated Fiberglass Sleeve is a vital protective solution for industries that face harsh environmental conditions. Its ability to withstand extreme heat, abrasion, and chemical exposure ensures long-lasting protection for hoses, wires, and cables in challenging settings. With its ease of installation and wide-ranging capabilities, this sleeve is trusted by professionals across the automotive, aerospace, industrial, and power generation sectors. By extending the lifespan of components and minimizing the risk of failures, it enhances operational efficiency and reduces maintenance costs, making it an essential tool for any industry dealing with high temperatures and mechanical stress.